Choosing the right power supply feels complex. Pick wrong, and you face bulky designs, wasted energy, and higher costs. Let’s see why Switch Mode Power Supplies (SMPS) are often the superior choice today.

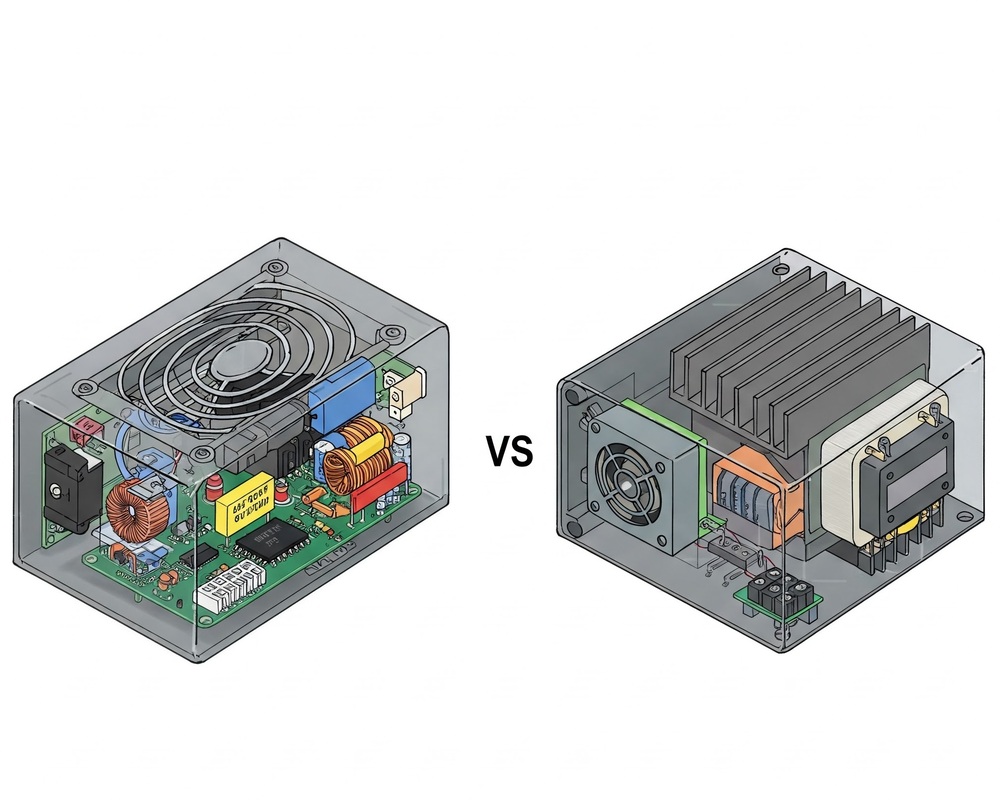

SMPS often wins because it offers much higher efficiency, is significantly smaller and lighter, and handles a wider input voltage range. This makes it ideal for most modern electronics compared to older linear designs.

Now, you might wonder if SMPS is always the best pick. Linear supplies still have their place. But for the demands of today’s electronics, understanding the specific advantages of SMPS is crucial. Let’s break down exactly why they usually come out on top.

How does efficiency make SMPS a better choice?

Wasted energy in a power supply means excess heat and higher running costs. This inefficiency can hurt your product’s performance and even its lifespan. See how the high efficiency of SMPS saves energy and reduces heat problems.

SMPS achieves great efficiency, often between 80% and 95%. It does this by switching components fully on or off, minimizing energy wasted as heat. Linear supplies constantly burn off excess voltage as heat, making them much less efficient.

Let’s dive deeper into why this efficiency matters so much. In my years at Guangzhou Quankang Technology, helping designers like Jacky, efficiency is always a top concern.

Understanding the Efficiency Difference

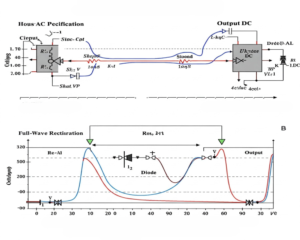

The core difference lies in how they regulate voltage. A linear regulator is like a variable resistor; it constantly adjusts resistance to drop excess input voltage down to the desired output voltage. All that dropped voltage turns directly into heat. Think of it like driving your car with the brakes slightly on all the time – you’re wasting energy.

An SMPS works differently. It chops up the input voltage using high-frequency switching (turning components fully on or fully off very quickly). Then, it uses components like inductors and capacitors to smooth this chopped voltage into a stable DC output. Because the switching elements are either fully on (low resistance, low power loss) or fully off (no current, no power loss), very little energy is wasted as heat during the regulation process itself.

Practical Impacts of High Efficiency

Higher efficiency translates to several key benefits for product designers:

- Less Heat: Less wasted energy means less heat generated. This simplifies thermal management. You might need smaller heatsinks, or perhaps no heatsink at all. This saves space and cost, crucial for compact devices.

- Lower Operating Costs: For the end-user, less wasted electricity means lower energy bills, especially for devices that are always on.

- Meeting Standards: Global efficiency standards, like the US Department of Energy’s Level VI (DoE VI), mandate high efficiency for external power supplies. SMPS technology is essential to meet these regulations.

- Component Longevity: Lower operating temperatures generally lead to longer lifespans for electronic components within the power supply and the device it powers.

Here’s a simple comparison:

| Feature | Linear Power Supply | Switched-Mode Power Supply (SMPS) | Why it Matters for Designers (like Jacky) |

|---|---|---|---|

| Efficiency | Typically 30-60% | Typically 80-95%+ | Lower energy waste, less heat, easier thermal management, meets DoE VI standards |

| Heat Output | High | Low | Smaller/no heatsinks needed, improves reliability, enables compact designs |

| Energy Costs | Higher | Lower | Important selling point for end-users, compliance with eco-design regulations |

For someone like Jacky, focused on cost-effective, innovative consumer electronics under tight deadlines, the efficiency gains from SMPS directly address major challenges. It helps manage costs (less cooling needed), meet regulations, and improve the end product’s appeal.

Does the smaller size and weight of SMPS matter?

Bulky power supplies can seriously limit your product’s design potential. Heavy components also add to shipping costs and can make devices less user-friendly. Let’s explore the significant size and weight advantage SMPS offers.

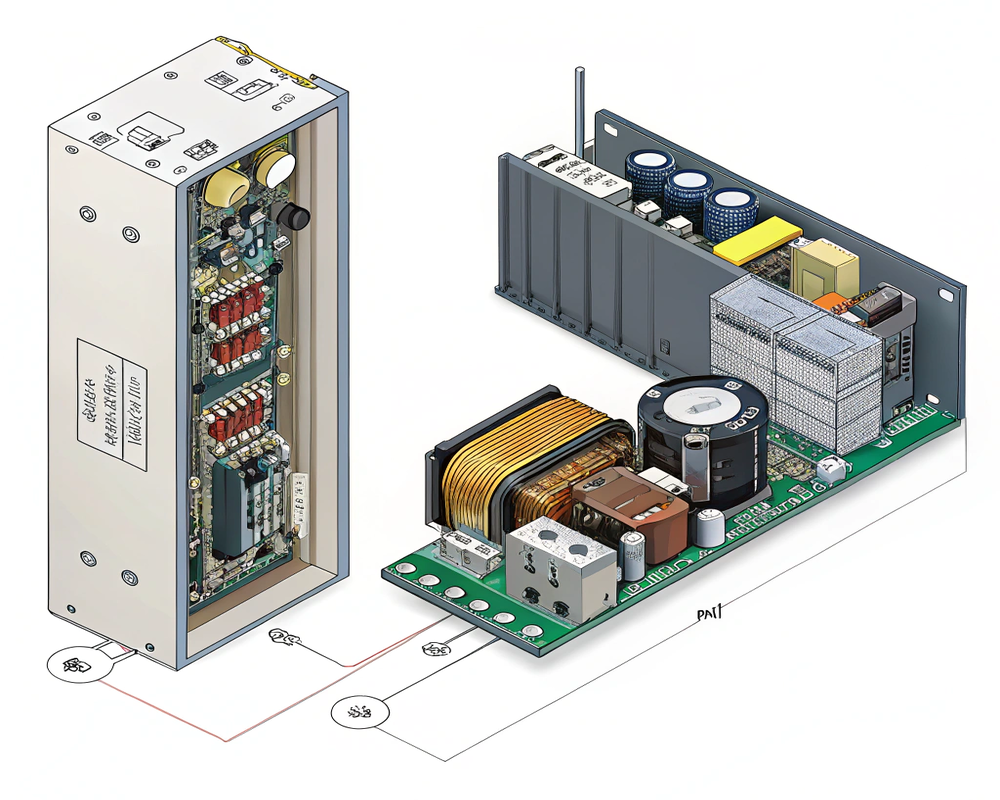

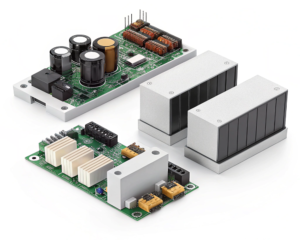

Yes, size and weight matter a lot. SMPS uses high-frequency transformers and capacitors which are much smaller and lighter than the large, heavy low-frequency transformers needed in linear supplies for the same power output.

Let’s look closer at why SMPS achieves this reduction and what it means practically. I often see designers struggle with fitting everything into sleek, modern casings. The power supply choice directly impacts this.

The High-Frequency Advantage

The key is the operating frequency. Linear power supplies operate at the mains frequency (typically 50Hz or 60Hz). At these low frequencies, transformers need large iron cores and many copper windings to handle the required power. This makes them inherently big and heavy.

SMPS operates at much higher frequencies, often from tens of kilohertz (kHz) up to megahertz (MHz). The physics of transformers dictates that as frequency increases, the size of the magnetic core and the amount of copper needed for the windings can decrease dramatically for the same power transfer. It’s a fundamental relationship: higher frequency allows for smaller magnetic components (transformers and inductors). Similarly, capacitors used for filtering also become smaller at higher frequencies.

Implications for Product Design and Logistics

This reduction in size and weight has huge implications:

- Compact Product Design: SMPS allows for much smaller and slimmer end products. Think about modern laptops, phone chargers, and flat-screen TVs – their sleekness is partly thanks to compact SMPS technology. For Jacky, designing mobile phones and tablets, this is absolutely critical.

- Portability: Lighter devices are easier for consumers to carry and use.

- Material Savings: Smaller components mean less raw material (iron, copper, plastic casing), which can lower manufacturing costs.

- Shipping Costs: Lighter and smaller products mean lower shipping and logistics expenses, especially when shipping globally in large volumes.

- Design Flexibility: The space saved by using an SMPS gives designers more room for other features or allows for more aesthetically pleasing designs. This helps products stand out in competitive markets.

Here’s how they stack up physically:

| Feature | Linear Power Supply | Switched-Mode Power Supply (SMPS) | Why it Matters for Designers (like Jacky) |

|---|---|---|---|

| Operating Freq. | Low (50/60 Hz) | High (kHz – MHz range) | Enables use of much smaller magnetic components. |

| Transformer Size | Large, Bulky | Small, Compact | Saves significant space inside the product. |

| Overall Size | Large | Small | Allows for slimmer, more aesthetically pleasing product designs. |

| Weight | Heavy | Light | Reduces material cost, shipping cost, and improves device portability. |

| Power Density | Low (Watts per cubic inch) | High (Watts per cubic inch) | More power in less space, crucial for miniaturization trends. |

For Jacky, who needs to balance innovation, cost, and fast development cycles (6-18 months), the physical advantages of SMPS are undeniable. They enable the creation of the compact, lightweight, and cost-effective consumer electronics demanded by the market.

What about input voltage range and performance?

Having a power supply fail just because the input voltage is slightly off is a major headache. Also, unstable power output can damage the sensitive electronics inside your device. Let’s see how SMPS generally handles varying input voltages better.

SMPS excels here. It typically accepts a very wide AC input voltage range automatically, like 90V to 264V. This ‘universal input’ makes products suitable for global use without needing different versions or manual switches.

Understanding this capability is vital, especially for companies selling products internationally. Based on my experience at Quankang, ensuring global compatibility is a common requirement from clients like Jacky’s company.

Handling Global Power Grids

Linear power supplies are often designed for a specific nominal input voltage (like 120V AC or 230V AC) with a limited tolerance (maybe +/- 10%). To sell globally, you might need different models for different regions, or include voltage selector switches or input transformer taps. This adds complexity and cost.

SMPS, however, uses a feedback control loop. This loop constantly monitors the output voltage and adjusts the switching pattern (specifically, the ‘duty cycle’ – how long the switch stays on versus off) to keep the output stable, even if the input voltage fluctuates significantly. This inherent design allows most SMPS units to operate seamlessly across the typical voltage ranges found worldwide (roughly 90V AC to 264V AC) without any user intervention.

Performance Considerations: Regulation and Noise

While SMPS wins on input range, performance nuances exist:

- Output Regulation: Both types can provide well-regulated output voltage. SMPS uses its feedback loop to maintain tight regulation across varying loads and input voltages. Linear regulators also offer good regulation, sometimes even slightly better under steady load conditions.

- Ripple and Noise: This is where linear supplies traditionally had an edge. Linear regulators produce a very clean DC output with very low ripple and noise. SMPS, due to its high-frequency switching nature, inherently generates more high-frequency noise on its output. While advanced SMPS designs incorporate filtering to minimize this noise, highly sensitive analog or audio circuits might still perform better with a well-designed linear supply. However, for most digital electronics, including phones and tablets Jacky works on, the noise levels from a modern SMPS are perfectly acceptable.

- Transient Response: How quickly the supply reacts to sudden changes in load current. SMPS designs can sometimes have a slightly slower transient response than linear regulators, though modern designs have largely overcome this.

Let’s compare these operational aspects:

| Feature | Linear Power Supply | Switched-Mode Power Supply (SMPS) | Why it Matters for Designers (like Jacky) |

|---|---|---|---|

| Input Voltage Range | Narrow, often region-specific | Wide (Universal Input: ~90-264V AC) | Simplifies inventory, allows global product rollout, reduces design variants. |

| Output Regulation | Good to Excellent | Good to Excellent | Both maintain stable output voltage under varying conditions. |

| Output Ripple/Noise | Very Low | Higher (High-Frequency Switching Noise) | Linear better for ultra-sensitive circuits; SMPS usually fine for digital logic. |

| Complexity | Simpler Design | More Complex Design | SMPS potentially has more failure points but offers more features. |

| Cost | Cheaper at very low power (<5-10W) | Often cheaper at higher power levels | Cost-effectiveness depends heavily on power rating and features. |

For Jacky, whose company sells consumer electronics globally, the universal input range of SMPS is a massive advantage. It simplifies logistics and ensures products work reliably for customers everywhere. While noise needs consideration, for the target devices (phones, tablets), SMPS performance is generally more than adequate and the benefits far outweigh this potential drawback.

Conclusion

In most cases, SMPS is better than linear power supplies. Key advantages are higher efficiency, smaller size, lighter weight, and wider input voltage range, making them ideal for modern electronics.